News

Common Consumables for Diesel Generator Sets

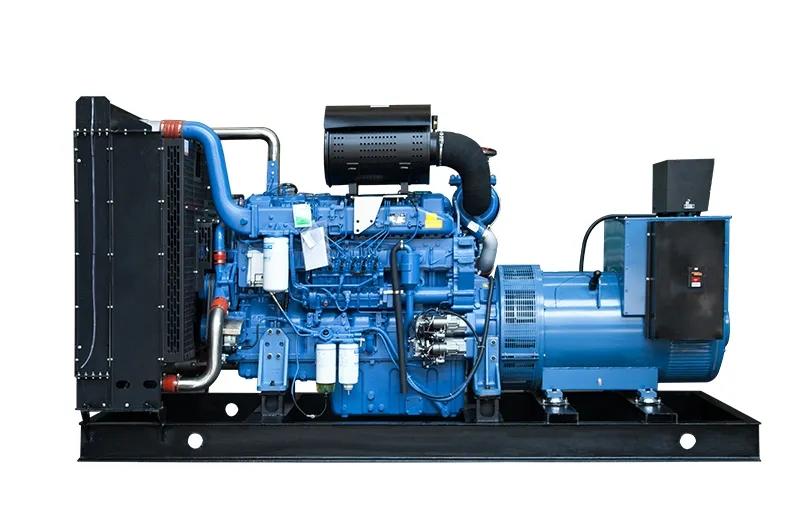

Diesel generators are essential for providing reliable backup power for homes, businesses, and industrial applications. To ensure that these machines operate efficiently and last a long time, regular maintenance is required. One of the key aspects of maintenance is replacing various consumable parts that can wear out over time. These consumables help in keeping the diesel generator running smoothly and prevent unexpected breakdowns. In this article, we will discuss the most commonly used consumables for diesel generator sets.

1. Fuel Filter

The fuel filter is a critical component in ensuring that the diesel engine receives clean fuel. It prevents contaminants such as dirt, water, and rust from entering the engine, which could cause serious damage. Over time, the fuel filter can become clogged and ineffective, requiring replacement. Regularly replacing the fuel filter is essential for maintaining engine performance and efficiency.

2. Oil Filter

The oil filter plays a crucial role in keeping the engine’s oil free from impurities. As the diesel engine runs, it generates heat and friction, which can cause the oil to degrade and pick up dirt and metal particles. The oil filter removes these contaminants to prevent engine damage. Replacing the oil filter during oil changes is a standard maintenance practice that ensures the engine operates smoothly and avoids unnecessary wear and tear.

3. Air Filter

The air filter prevents dirt, dust, and other debris from entering the engine’s combustion chamber. Clean air is essential for the proper functioning of the diesel engine. If the air filter becomes clogged, it can restrict airflow, causing the engine to work harder and reducing its efficiency. Replacing the air filter at regular intervals ensures that the engine receives sufficient clean air for combustion, optimizing performance and fuel economy.

4. Coolant

The coolant is responsible for regulating the engine’s temperature and preventing it from overheating. Diesel generators generate significant heat during operation, and the coolant absorbs and dissipates this heat. Over time, coolant can degrade or leak, which can lead to overheating and engine damage. Regular checks and replacement of the coolant are necessary to maintain optimal engine temperature and prevent costly repairs.

5. Battery

The battery in a diesel generator set provides the power needed to start the engine. Batteries can wear out over time due to the repeated charge and discharge cycles. If the battery is not functioning properly, the generator may fail to start, resulting in downtime. Replacing the battery at regular intervals is crucial for ensuring reliable startup and smooth operation of the diesel generator.

6. Belts and Hoses

Belts and hoses are essential components that help the generator’s engine function properly. Belts drive various systems such as the alternator, while hoses carry coolant, fuel, and oil throughout the engine. Over time, belts can become worn out, and hoses can crack or leak. Regular inspection and replacement of these components are vital to prevent system failure and maintain efficient operation.

7. Spark Plugs

For diesel engines that have them, spark plugs are essential for the ignition process. While most diesel engines rely on compression ignition, some may have spark plugs for certain functions, especially in hybrid systems. These plugs can wear down, causing misfires or inefficient combustion. Replacing spark plugs as part of routine maintenance ensures smooth engine operation and prevents performance issues.

8. Exhaust Filters

Exhaust filters are used to reduce harmful emissions produced by the diesel engine. These filters capture particulate matter and other pollutants before they are released into the atmosphere. Over time, exhaust filters can become clogged and reduce engine efficiency. Replacing these filters regularly ensures that the diesel generator meets environmental standards and operates efficiently.

9. Lubricants and Additives

Lubricants and additives are essential for maintaining engine health. Diesel engines require high-quality oil to reduce friction and wear. Additives are often used to enhance the oil’s properties, such as improving fuel efficiency, reducing engine deposits, and protecting against corrosion. Regularly changing the oil and using the right additives is crucial for maximizing the lifespan and performance of the diesel generator.

10. Seals and Gaskets

Seals and gaskets prevent leaks of fluids such as fuel, oil, and coolant. Over time, these parts can degrade due to heat, pressure, and exposure to harsh operating conditions. Replacing worn-out seals and gaskets is necessary to prevent fluid leaks, which could lead to engine damage and costly repairs.

Proper maintenance of a diesel generator set is essential for ensuring reliable power supply and extending the lifespan of the equipment. By regularly replacing the consumable parts such as fuel filters, oil filters, air filters, coolant, and others, you can prevent unexpected breakdowns and optimize the generator’s performance. Always consult the manufacturer’s guidelines for the recommended maintenance schedule and use high-quality consumables to ensure the best results. A well-maintained diesel generator will provide efficient and reliable power when you need it most.

Categories

News

Contact Us

Contact: yuchai Generator Set

Phone: +86 13312561188

Tel: +86-0871-67352758

E-mail: master@zimbon.com

Add: 11th Floor, Office Building C, Shuangcheng Intercity Business Center, No. 8868 Guangfu Road, Guandu District, Kunming City, Yunnan Province, China